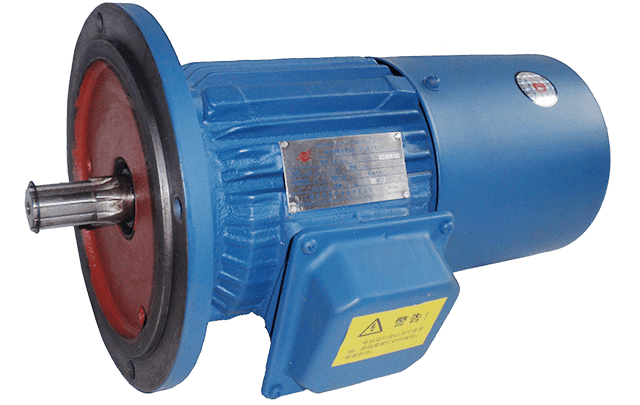

YSE Series Solid Rotor Soft Start Motor (R1)

Product Description

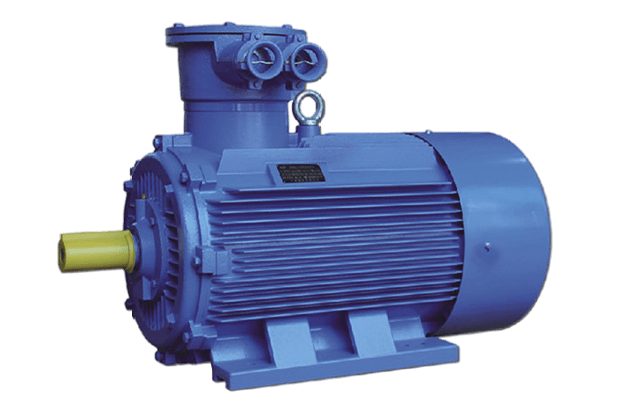

YSE motor has relatively soft mechanical characteristics, that is, large stall torque, large slip, and slow acceleration. Therefore, the crane can be equipped with a YSE motor to obtain a slow start effect, so that the impact phenomenon can be greatly improved when the crane starts. (It can replace the wound rotor motor, thereby eliminating the need for external resistors and electronic control components such as cam controllers, saving costs, reducing failures, and improving reliability)

This series of motors has a small locked-rotor current, which can meet the needs of frequent starting and jogging of the crane. The motor winding will not burn out for 6-7 minutes after the motor is locked. It is equipped with a plane AC brake, and the braking torque can be adjusted arbitrarily. The crane stops Slow stop operation can be obtained when there is no impact.

Four advantages / outstanding features of YSE series:

Soft start Walking without impact.

Large starting force can work continuously for 8 hours.

Lightweight and energy-saving 1/4 current start energy saving and environmental protection.

Strong practicability Adapt to high temperature environment operation.

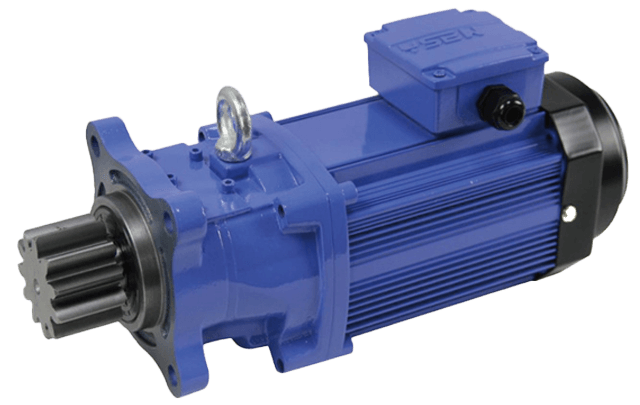

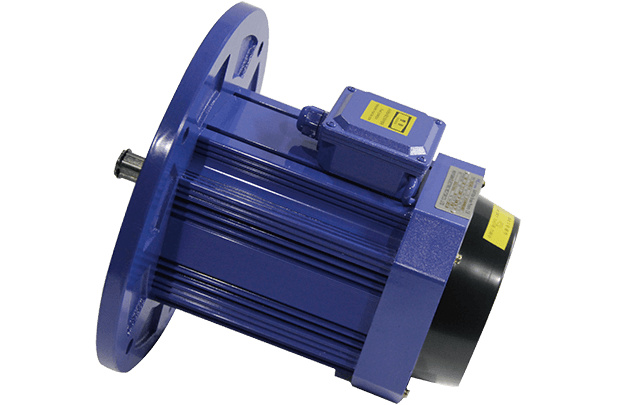

Structure and Principle

The YSE series soft start brake motor (3rd generation) is a power loss brake motor, and its DC disc brake is installed on the end cover of the non axial extension end of the motor. The working principle is that when the motor is connected to the power supply, the rectifier of the brake is also connected to the power supply due to the electromagnetic attraction. The electromagnet attracts the armature and compresses the spring, causing the brake disc to detach from the armature and end cover, causing the motor to operate. When the power is cut off, the brake electromagnet loses electromagnetic attraction, and the spring force pushes the armature to compress the brake disc. Under the action of the frictional torque, the motor immediately stops rotating.

The first generation soft start motor (R1) solid rotor AC brake-parameters

| Seat No. | Power | Voltage | Frequency | work system | Protectionlevel | Insulationlevel |

| 80~160 | 0.4~15KW | 380v | 50HZ | S3 40% | IP54 | F |

YSE series technical parameters

| Type | Power(D.KW) | Blocking Torque(D.N·M) | BlockingCurrent(D·A) | Rated speed(r/min) | Synchronous speed(r/min) | Brake torque(BK-N·M) | |

| 4-level | 801-4 | 0.4 | 4 | 2.8 | 1200 | 1500 | 1-6 |

| 802-4 | 0.8 | 8 | 3.6 | 1-6 | |||

| 90S-4 | 1.1 | 12 | 6.2 | 1-6 | |||

| 90L-4 | 1.5 | 16 | 7.5 | 2-10 | |||

| 100L1-4 | 2.2 | 24 | 10 | 2-10 | |||

| 100L2-4 | 3 | 30 | 12 | 3-20 | |||

| 112M-4 | 4 | 40 | 17 | 3-30 | |||

| 132S-4 | 5.5 | 52 | 24 | 3-30 | |||

| 132M-4 | 7.5 | 76 | 32 | 10-40 | |||

| 160M-4 | 11 | 116 | 58 | 10-40 | |||

| 160L-4 | 15 | 150 | 75 | 20-50 | |||

| 180M-4 | 18.5 | 185 | 92 | 20-50 | |||

| 180L-4 | 22 | 220 | 110 | 20-60 | |||

| 200L-4 | 30 | 300 | 170 | 20-60 | |||

| 225S-4 | 37 | 370 | 190 | 20-60 | |||

| 225M-4 | 45 | 450 | 248 | 30-80 | |||

| 250-4 | 55 | 550 | 380 | 30-80 | |||

| 280-4 | 75 | 750 | 430 | 75-250 | |||

| 280-4 | 90 | 900 | 510 | 75-250 | |||

| 315-4 | 110 | 1100 | 600 | 150-450 | |||

| 315-4 | 132 | 132 | 780 | 150-450 | |||

| 315-4 | 160 | 1600 | 940 | 150-450 | |||

| 315-4 | 200 | 2000 | 1200 | 150-450 | |||

| 6-level | 80M2-6 | 0.4 | 8 | 4 | 800 | 1000 | 2-10 |

| 90S-6 | 0.8 | 12 | 5 | 2-10 | |||

| 90L-6 | 1.1 | 23 | 8 | 3-20 | |||

| 100L-6 | 1.5 | 33 | 11.5 | 3-20 | |||

| 112M-6 | 2.2 | 46 | 16 | 3-30 | |||

| 132S-6 | 3 | 60 | 19 | 10-40 | |||

| 132M1-6 | 4 | 82 | 25 | 10-40 | |||

| 132M2-6 | 5.5 | 112 | 42.5 | 10-40 | |||

| 160M-6 | 7.5 | 160 | 52 | 20-50 | |||

| 160L-6 | 11 | 235 | 64 | 20-50 | |||

| 180L-6 | 15 | 270 | 88 | 20-60 | |||

| 200L1-6 | 18.5 | 320 | 110 | 30-70 | |||

| 200L2-6 | 22 | 435 | 150 | 30-70 | |||

| 225M-6 | 30 | 540 | 180 | 30-80 | |||

| 250-6 | 37 | 660 | 220 | 30-80 | |||

| 280-6 | 45 | 810 | 270 | 75-250 | |||

| 280-6 | 55 | 990 | 330 | 75-250 | |||

| 315-6 | 75 | 1350 | 450 | 150-450 | |||

| 315-6 | 90 | 1620 | 540 | 150-450 | |||

| 315-6 | 110 | 1980 | 650 | 150-450 | |||

| 315-6 | 132 | 2300 | 795 | 150-450 | |||

| 8-level | 80M-8 | 0.4 | 8 | 3.7 | 600 | 750 | 1-6 |

| 90M-8 | 0.8 | 16 | 6 | 1-6 | |||

| 90L-8 | 1.1 | 22 | 8.5 | 2-10 | |||

| 100M-8 | 1.5 | 32 | 11 | 3-30 | |||

| 112S-8 | 2.2 | 48 | 14.8 | 3-30 | |||

| 132M-8 | 3 | 60 | 18 | 10-40 | |||

| 160M1-8 | 4 | 80 | 23 | 10-40 | |||

| 160M2-8 | 5.5 | 100 | 27 | 20-50 | |||

| 160L-8 | 7.5 | 150 | 36 | 20-50 | |||

| 180L-8 | 11 | 220 | 53 | 20-60 | |||

| 200L-8 | 15 | 300 | 70 | 30-70 | |||

| 225S-8 | 18.5 | 370 | 88 | 30-80 | |||

| 225M-8 | 22 | 450 | 110 | 30-80 | |||

| 250-8 | 30 | 600 | 160 | 75-250 | |||

| 280-8 | 37 | 740 | 200 | 75-250 | |||

| 280-8 | 45 | 900 | 244 | 75-250 | |||

| 315-8 | 55 | 1100 | 300 | 150-450 | |||

| 315-8 | 75 | 1500 | 410 | 150-450 | |||

| 315-8 | 90 | 1800 | 490 | 150-450 | |||

| 315-8 | 110 | 220 | 600 | 150-450 | |||

| 10-level | 90L-10 | 0.4 | 11 | 3.2 | 480 | 600 | 2-10 |

| 100L-10 | 0.8 | 17 | 5.2 | 3-20 | |||

| 112M-10 | 1.5 | 40 | 10.8 | 3-20 | |||

| 132S-10 | 2.2 | 60 | 15 | 10-40 | |||

| 132M-10 | 3 | 80 | 17.5 | 10-40 | |||

| 160M1-10 | 4 | 110 | 22 | 20-50 | |||

| 160M2-10 | 5.5 | 150 | 29 | 20-50 | |||

| 160L-10 | 7.5 | 210 | 40 | 20-50 | |||

| 180M-10 | 11 | 300 | 55 | 20-60 | |||

| 180L-10 | 15 | 410 | 70 | 20-60 | |||

| 200L1-10 | 18.5 | 500 | 92 | 30-70 | |||

| 200L2-10 | 22 | 600 | 110 | 30-70 | |||

| 225M-10 | 30 | 820 | 148 | 30-80 | |||

| 12-level | 90L-12 | 0.4 | 6 | 3.5 | 400 | 500 | 2-10 |

| 100L-12 | 0.8 | 15 | 4 | 3-20 | |||

| 112M-12 | 1.5 | 37 | 9.6 | 3-20 | |||

| 132M-12 | 3 | 76 | 15.5 | 10-40 | |||

| 160L-12 | 5.5 | 148 | 34.5 | 20-50 | |||

| 180M-12 | 7.5 | 202 | 38 | 20-60 | |||

| 180L-12 | 11 | 285 | 47 | 20-60 | |||

| 200L1-12 | 15 | 376 | 60 | 30-70 | |||

| 225S-12 | 18.5 | 467 | 74 | 30-70 | |||

| 22MS-12 | 22 | 562 | 90 | 30-80 | |||

| 225M-12 | 30 | 760 | 130 | 30-80 | |||

| 16-level | 180M-16 | 3 | 98 | 32 | 300 | 375 | 20-60 |

| 180L-16 | 4 | 116 | 37 | 20-60 | |||

| 200L-16 | 4 | 116 | 37 | 20-60 | |||

| 225S-16 | 7.5 | 260 | 80 | 30-80 | |||

| 225S-16 | 11 | 390 | 110 | 30-80 | |||