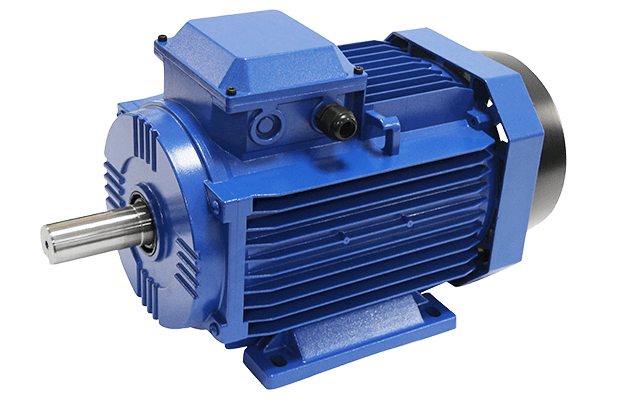

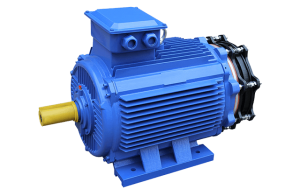

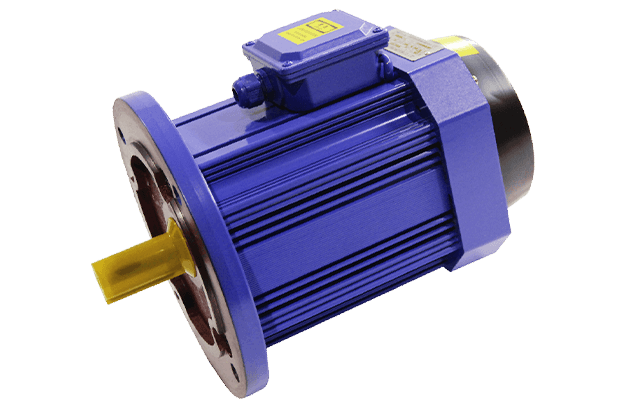

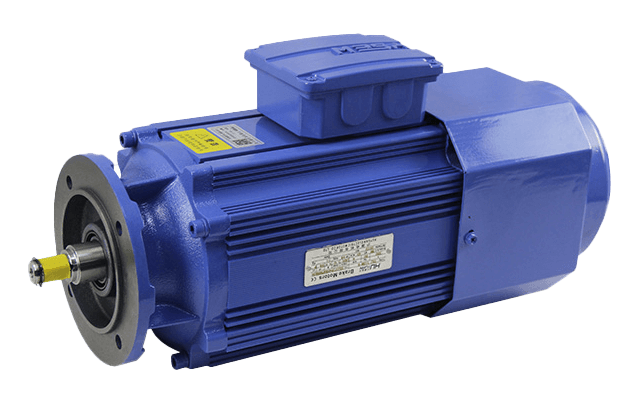

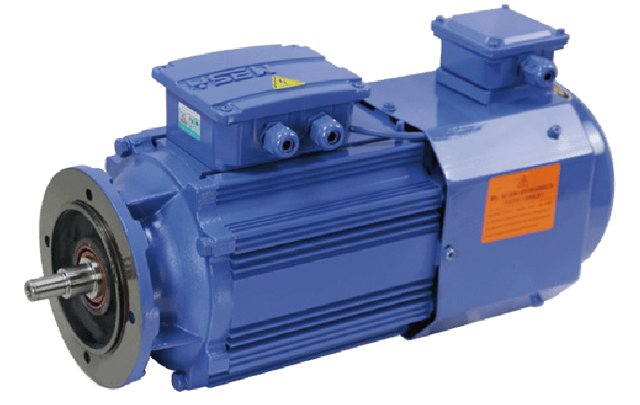

Premium Efficiency Three-Phase Asynchronous Motor

Product Description

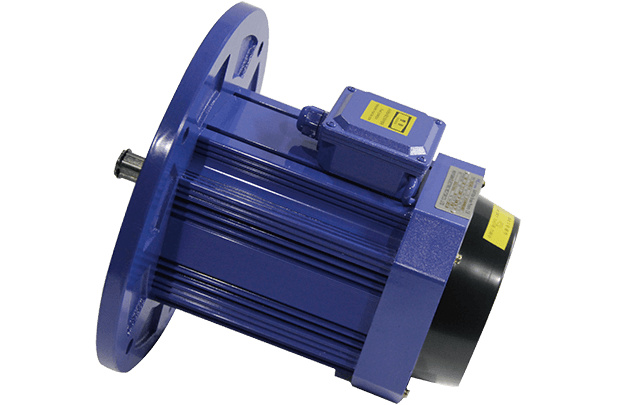

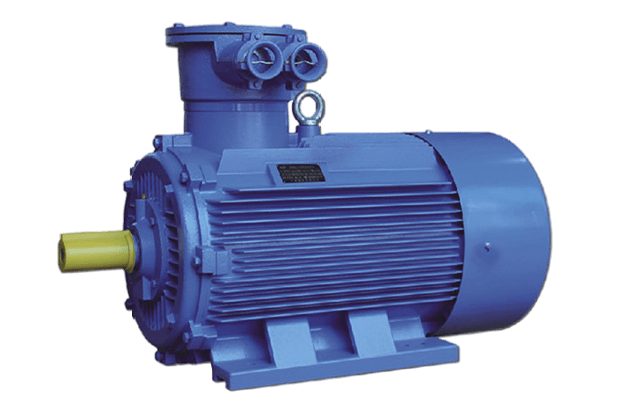

The dedicated motor for direct connected hard tooth surface reducers is designed specifically for the R, S, F, and K series of hard tooth surface reducers. Improvements and adjustments have been made to the flange end structure and bearing seat, which can be paired with multiple flange covers in the same model to meet the requirements of different installation sizes. It is directly connected to the hard tooth reducer and adopts a design of high efficiency, low noise, and high reliability. It can provide high torque, high precision, and long running time power support for industrial production lines, mechanical equipment, automated production lines, etc. It is particularly suitable for situations that require high-power, high-efficiency, and low noise motors.

Product Characteristic

1. High power density: The special motor for the direct connected hard tooth reducer adopts new materials and manufacturing process design, allowing the motor to provide higher power density in a smaller volume, meeting the application of high power requirements.

2. High efficiency: The motor adopts optimized magnetic circuit and winding design, which can achieve high efficiency, reduce energy consumption, and improve system efficiency.

3. High reliability: The motor bearings and wiring are made of special materials and designs to ensure long-term stable operation of the motor under high loads, temperatures, and corrosive environments.

4. High torque: The torque output by the motor is high, suitable for the high load generated during the operation of the hard tooth reducer, ensuring the stable operation of the equipment.

5. Low noise: The motor adopts precise processing technology, which reduces noise during operation and meets high noise requirements for occasions.

6. Easy installation: The motor is directly connected to the hard tooth reducer, without the need for other special equipment. The installation is simple, saving time and cost.

7. Long term maintenance: The motor has a simple structure, is easy to maintain and clean, and has a long service life.

In short, the dedicated motor for the direct connected hard tooth reducer can provide high-performance power support and meet various requirements, making it an ideal motor equipment.