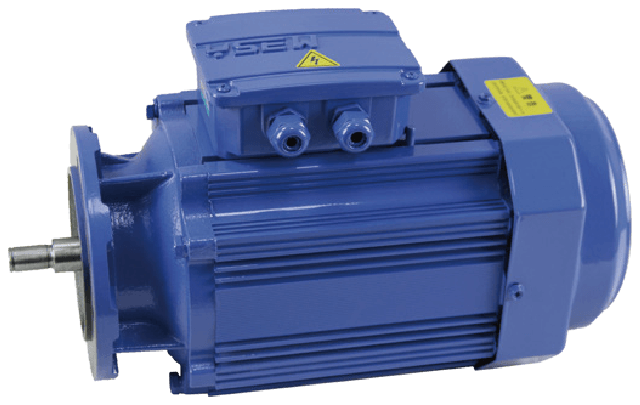

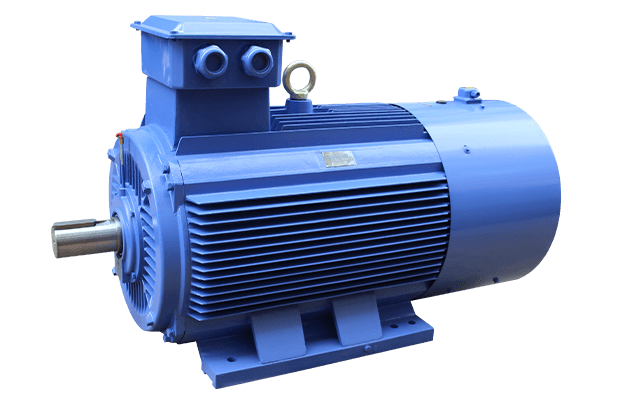

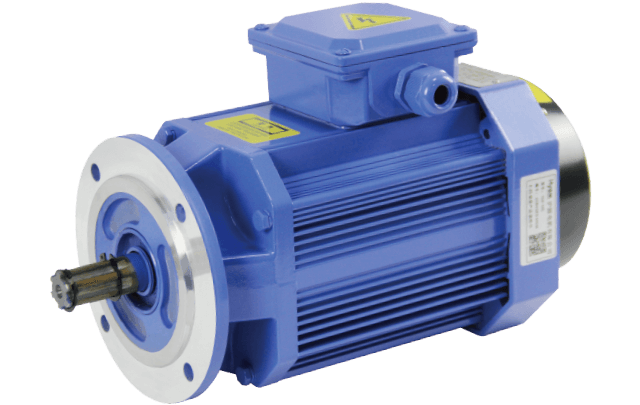

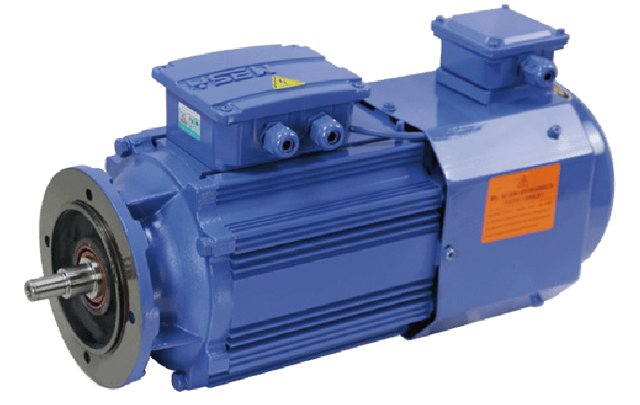

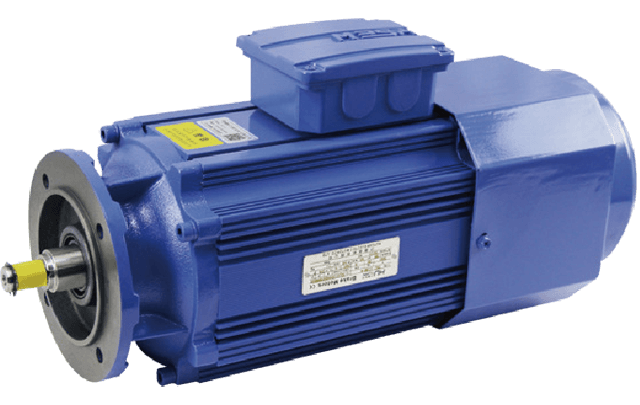

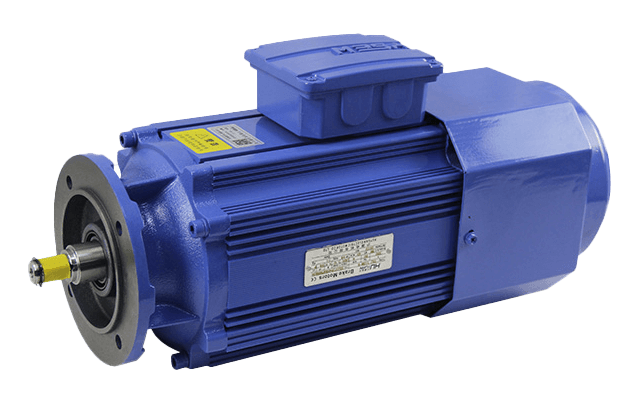

High Efficiency Hard Tooth Surface Reducer Special Direct Motor

Operation Condition

Ambient temperature: -15℃-+40℃

Duty: S1

Altitude: Not exceed 1000m

Cooling method: IC 0141(Fan cooling fan)

Rated voltage: 380V(Other voltages reguired separale agreement)

Rated frequency: 50Hz, 60Hz

Insulation c!ass: F

Protection class: IP54.IP55

Product Description

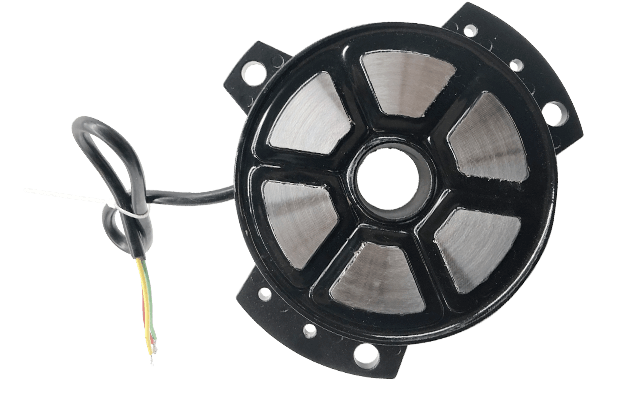

The direct connected hard tooth surface reducer dedicated variable frequency motor is a motor designed specifically for the hard tooth surface R, S, F, K series reducers. This series of motors adopts frequency converter control, which can achieve stepless adjustment of motor speed, thereby achieving the adjustment of motor power, and avoiding some shortcomings of traditional resistance speed regulation methods. At the same time, this series of motors has the characteristics of high efficiency and energy conservation, which can greatly reduce the energy consumption of the motor, thereby reducing the operating costs of the enterprise. And improvements and adjustments have been made to the flange end structure and bearing seat, which can be paired with multiple flange covers in the same model to meet the requirements of different installation sizes. It is directly connected to the hard tooth reducer and adopts a design of high efficiency, low noise, and high reliability. It can provide high torque, high precision, and long running time power support for industrial production lines, mechanical equipment, automated production lines, etc. It is particularly suitable for situations that require high-power, high-efficiency, and low noise motors.